EXPLORE

EXPLORE

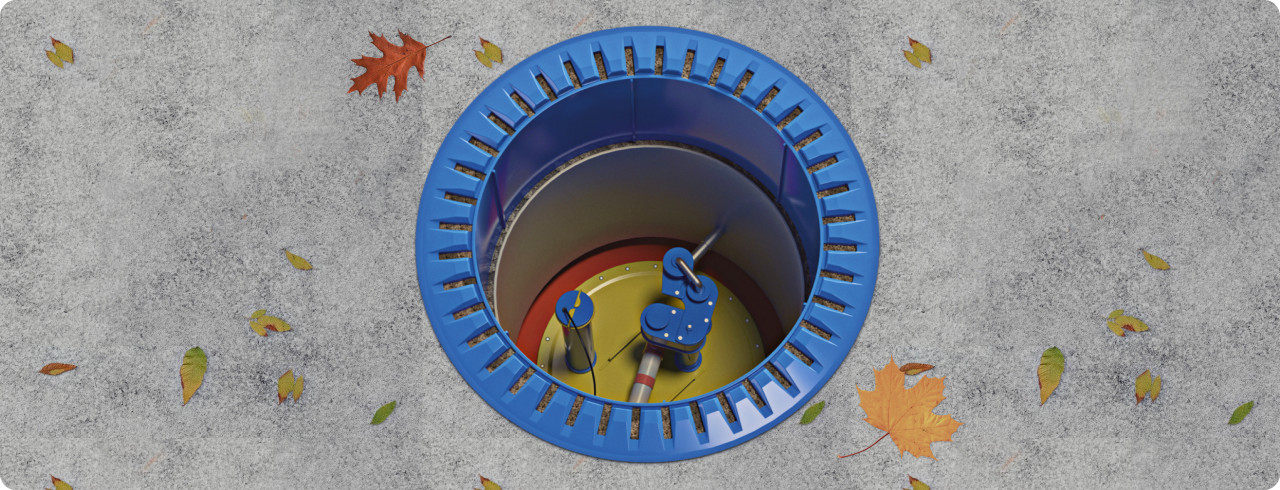

Eliminating Damage to Underground Equipment

PROBLEM

A common problem impacting owners of underground equipment, including gas stations, is surface water and contaminants leaking into the equipment from the surface, corroding or otherwise damaging the equipment.

Once this damage occurs, the underground equipment will eventually need to be repaired or, at worst, replaced.

SOLUTION

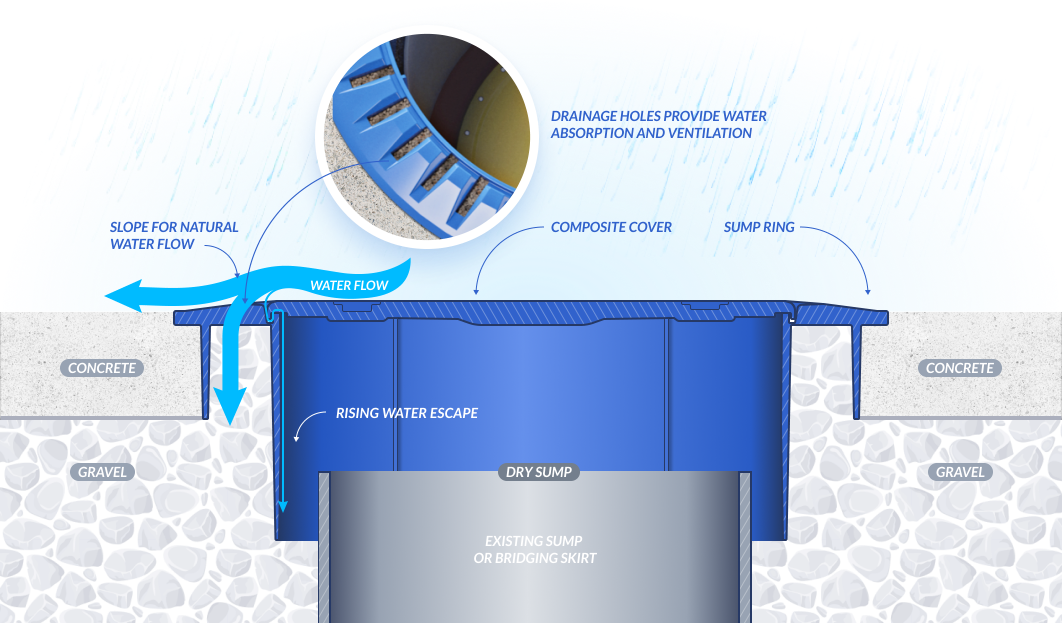

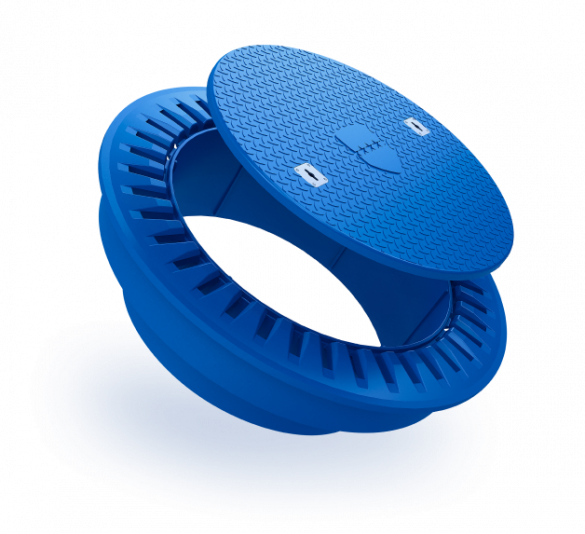

Constructed of a highly durable industrial-grade composite material, Pro Shield® is made to withstand the harshest environments and designed to direct surface water away from the equipment and into the surrounding gravel, leaving your equipment safe and dry.

- Stops water from infiltrating equipment

- Provides ventilation

- Provides an innovative method

- Saves up to $50,000 per tank

Completely Stop Water Infiltration

Our innovative, patented design (US9464401B2) does not use any type of sealing gaskets, instead it routes water into the drain, keeping it away from the equipment.

The solution fits on top of existing equipment, no need to rip and replace equipment, including gas station sumps.

Benefits

-

Saves 75% on parts and labor normally needed for retrofits

-

No business interruption during installation

-

No hinges, bolts, wearable or mechanical parts that need maintenance or replacement

-

Durable, performance does not degrade with time and never needs repainting

-

Eliminates water inflow, eliminating the need for monthly inspections and costly water disposal

-

30-year manufacturer warranty for peace of mind

290 BILMAR DR. PITTSBURGH, PA 15205